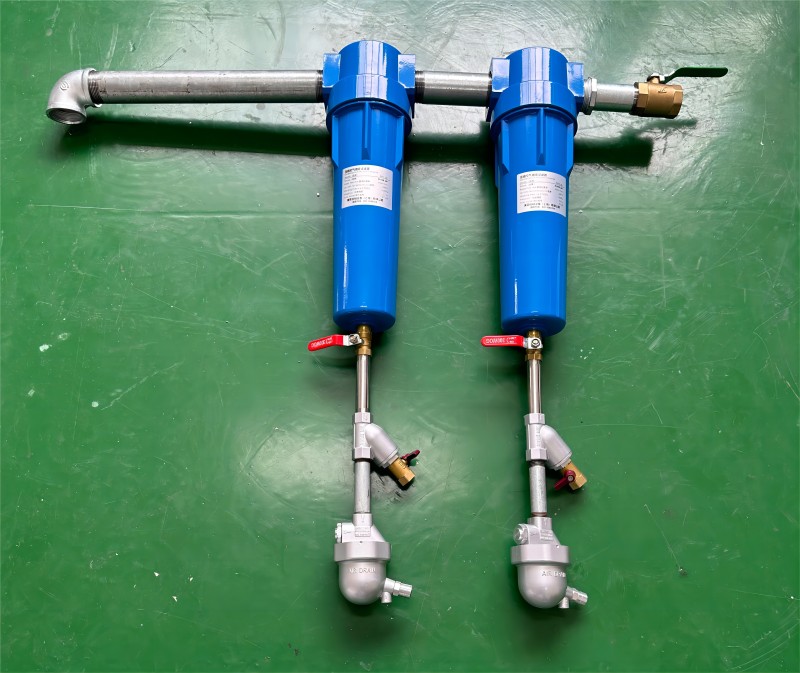

◆ 本系列分铝壳过滤器与法兰过滤器,新型铝壳过滤器采用优质铝合金材料制造,内外部皆喷涂环氧树脂粉末,以提高耐用性和抗腐蚀性;新型铝壳过滤器紧凑型设计,可串联连接,并节省空间,处理流量从0.7Nm3/min至18 Nm3/min;法兰过滤器从1Nm3/min至550 Nm3/min;

◆ 申昊HF系列为你提供高品质的压缩空气;一般的压缩空气系统会受到磨蚀性固体颗粒(如灰尘、赃物、铁锈与水垢)、压缩机润滑油(矿物或合成润滑油)、冷凝液滴和酸性冷凝水以及油气和烃蒸气污染。若不清除这些污染物,那么气动设备的维护成本会上升,造成仪表和控制系统故障,容易引发产品表面质量问题,并污染工艺过程。匹配的沪盛过滤器或其过滤系统将清除这些污染物,使您的压缩空气系统达到您应用所需的空气质量,这有助确保一致的输出质量,同时降低运营成本。

◆ 可选配件:自动排水器、压差显示器、压差指示表、液面指示器。

过滤器滤芯五种级别介绍

可选用五种过滤器(分为国产/进口滤芯)供您设计确保所需质量的供气系统

A choice of five elements allows you to design a system that delivers

The air quality you require

-------------------------------------------------------------------------------------------------------

◆ 按入式过滤器,便于迅速更换

◆ 活塞型过滤器芯与壳体密封,防止未过滤的气体绕过过滤器

◆ 防腐蚀滤芯:不锈钢芯以增强结构性能、气流阻力低、采用缝焊以提高强度

◆ 新型“矩阵混合纤维”介质:有效表面积大,改进滤除率,确保高效率;开放区大,尽量减少压降

◆ 涂膜封闭式泡沫套筒:抗油类和酸类的化学腐蚀;防止聚结液体重新混入气流,确保高效滤除

◆ 防化学腐蚀的端盖用特制粘接剂粘接到介质上,不含硅树脂

◆ 可承受66℃高温

Separator filter (C)

-----------------------------------------------------------------------------------------------------------------------------------------

| 适用于滤除大量液体和3微米大小的凝聚物(5ppm w/w最大残留油分含量) ◆双级过滤 ◇第1级-两根不锈孔管,进行10微米机械分离 ◇第2级-深层纤维介质滤除3微米的固态和液态颗粒 | For bulk liquid removal plus a 3 micron coalescer (5ppm w/w maximum remaining oil content) ◆Two-stage filtration ◇First stage—two stainless steel orifice tubes provide 10 micron mechanical separation ◇Second stage—in-depth fiber media captures solid and liquid particles to 3 micron |

主管路过滤器(T级)

Air line filter(T)

-----------------------------------------------------------------------------------------------------------------------------------------

| 适用于滤除液态水和油:可滤除小至1微米大小的固态颗粒(1.0ppm w/w最大残留油分含量) ◆内/外滤芯皆防腐蚀 ◆双级过滤 ◇第1级-纤维介质和介质滤网交替叠层,滤除较大的颗粒 ◇第2级-多层环氧树脂粘合混合纤维介质,聚结油雾和滤除固态颗粒 | For removal of liquid water and oil; removes solid particles to 1 micron (1.0 ppm w/w maximum remaining oil content) ◆Corrosion resistant inner and outer cores ◆Two-stage filtration ◇First stage—captures larger particles with alternate layers of fiber media and media screen ◇Second stage—coalesces aerosols and captures solid particles with multiple layers of epoxy bonded, blended fiber media |

微油雾过滤器(A级)

High efficiency oil removal filter (A)

-----------------------------------------------------------------------------------------------------------------------------------------

| 适用于聚结细小的水汽和油雾;可滤除小至0.01微米的凝聚物(0.01ppm w/w最大残留油分含量) ◆内/外滤芯皆防腐蚀 ◆双级过滤 ◇第1级-多层纤维介质和介质滤网,滤除较大的颗粒,在空气进入第2级过滤前进行预过滤 ◇第2级-多层粘合混合纤维介质,滤除细小的凝聚物 ◆外涂膜封闭式泡沫套筒 | For coalescing fine water and oil aerosols; removes solid particles to 0.01 micron (0.01 ppm w/w maximum remaining oil content) ◆Corrosion resistant inner and outer cores ◆Two stage filtration ◇First stage—multiple layers of bonded, blended fiber media for fine coalescence ◇Second stage—multiple layers of bonded, blended fiber media for fine coalescence ◆Outer coated, closed cell foam sleeve |

超高效微油雾过滤器(AA级)

Ultra high efficiency oil removal filter (AA)

-----------------------------------------------------------------------------------------------------------------------------------------

| 适用于聚结细小的水汽和油雾;可滤除小至0.01微米的凝聚物(0.01ppm w/w最大残留油分含量) ◆内/外滤芯皆防腐蚀 ◆双级过滤 ◇第1级-涂膜封闭式泡沫套筒,进行预过滤和气流分散 ◇第2级-多层矩阵混合纤维介质,滤除极细小的凝聚物 ◆外涂膜封闭式泡沫套筒 | For coalescing ultra-fine oil aerosols; removes solid particles to 0.01 micron (0.001 ppm w/w maximum remaining oil content) ◆Corrosion resistant inner and outer cores ◆Two stage filtration ◇First stage—coated, closed cell foam sleeve acts as pre-filter and flow disperser ◇Second stage—multiple layers of matrix blended fiber media for ultra-fine coalescence ◆Outer coated, closed cell foam sleeve |

除油蒸汽过滤器(H级)

Activated carbon air filter (H)

-----------------------------------------------------------------------------------------------------------------------------------------

| 适用于滤除活性炭通常可吸收的油蒸汽和碳氢化合物蒸汽;可滤除小至0.01微米的固态颗粒(0.003ppm w/w最大残留油分含量) ◆内/外滤芯皆防腐蚀 ◆双级过滤 ◇第1级-极精细的活性炭粉稳定层,可滤除绝大部分油蒸汽 ◇第2级-多层纤维介质,粘合微精滤活性炭粉,可滤除残余的油蒸汽 ◆多层精细介质,防止污染物游移 ◆外涂膜封闭式泡沫套筒 ,防止纤维游移 ◆在额定运行条件下,设计寿命可达到1000小时 | For removal of oil and hydrocarbon vapors normally absorbable by activated carbon; removes solid particles to 0.01 micron (0.003 ppm w/w maximum remaining oil content) ◆Corrosion resistant inner and outer cores ◆Two stage filtration ◇First stage—a stabilized bed of finely divided carbon particles removes the majority of the, oil vapor ◇Second stage—multiple layers of fiber media with bonded micro fine carbon particles removes the remaining oil vapor ◆Multiple layers of fine media prevent particle migration ◆Outer coated, closed cell foam sleeve prevents fiber migration ◆Designed for 1000 hour life at rated conditions. |

(1)过滤器效率按照CAGI标准ADF400条确定,其计算基础是38℃进口气流温度。

(2)过滤器效率按照CAGI标准ADF500条确定,其计算基础是38℃进口气流温度。

(1)Filter efficiencies have been established in accordance with CAGI standard ADF 400 and are based on 100℉(38℃) inlet tem, perature.

(2)Filter efficiencies have been established in accordance with CAGI standard ADF 500 and are based on 100℉(38℃) inlet temperature.

可选配件

Optional parts

---------------------------------------------------------------------------------------------------------

压差指示表 电子排水器 Differential pressure gauge electric drain

压差指示器 自动排水器 pressure indicator auto-drain

型号规格与性能参数

Model, Size & Technical Data

规格型号model | 处理量 capacity | 滤芯支数 element quantity | 外型尺寸dimensions(mm) | 接口尺寸 air connection | 设备净重 net weight (kg) | |||||

C- | T- | A- | AA- | H- | A(宽width) | B(高height) | ||||

0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 1 | 105 | 160 | ZG1” | 5 |

1 | 1 | 1 | 1 | 1 | 1.2 | 1 | 105 | 210 | ZG1” | 5 |

2 | 2 | 2 | 2 | 2 | 2.4 | 1 | 105 | 275 | ZG1” | 8 |

4 | 4 | 4 | 4 | 4 | 3.8 | 1 | 133 | 295 | ZG11/2” | 10 |

5 | 5 | 5 | 5 | 5 | 5 | 1 | 133 | 420 | ZG11/2” | 10 |

7 | 7 | 7 | 7 | 7 | 7 | 1 | 164 | 510 | ZG11/2” | 15 |

8 | 8 | 8 | 8 | 8 | 8.5 | 1 | 164 | 550 | ZG11/2” | 25 |

10 | 10 | 10 | 10 | 10 | 11 | 1 | 164 | 625 | ZG2” | 25 |

13 | 13 | 13 | 13 | 13 | 13.8 | 1 | 194 | 730 | ZG2” | 25 |

18 | 18 | 18 | 18 | 18 | 18 | 1 | 310 | 920 | DN80/ ZG2” | 35 |

22 | 22 | 22 | 22 | 22 | 22 | 1 | 310 | 920 | DN80 | 35 |

26 | 26 | 26 | 26 | 26 | 26 | 2 | 475 | 1038 | DN80 | 80 |

35 | 35 | 35 | 35 | 35 | 35 | 2 | 475 | 1038 | DN80 | 85 |

45 | 45 | 45 | 45 | 45 | 45 | 2 | 475 | 1038 | DN100 | 90 |

54 | 54 | 54 | 54 | 54 | 54 | 3 | 525 | 1070 | DN125 | 125 |

66 | 66 | 66 | 66 | 66 | 66 | 3 | 608 | 1110 | DN125 | 135 |

88 | 88 | 88 | 88 | 88 | 88 | 4 | 617 | 1186 | DN125 | 145 |

110 | 110 | 110 | 110 | 110 | 110 | 5 | 617 | 1186 | DN150 | 150 |

132 | 132 | 132 | 132 | 132 | 132 | 6 | 612 | 1270 | DN150 | 210 |

150 | 150 | 150 | 150 | 150 | 154 | 7 | 612 | 1270 | DN200 | 220 |

180 | 180 | 180 | 180 | 180 | 180 | 10 | 662 | 1320 | DN200 | 235 |

200 | 200 | 200 | 200 | 200 | 200 | 11 | 662 | 1320 | DN200 | 240 |

230 | 230 | 230 | 230 | 230 | 234 | 13 | 730 | 1366 | DN200 | 265 |

250 | 250 | 250 | 250 | 250 | 252 | 14 | 730 | 1366 | DN200 | 280 |

280 | 280 | 280 | 280 | 280 | 288 | 16 | 802 | 1446 | DN250 | 335 |

300 | 300 | 300 | 300 | 300 | 310 | 17 | 855 | 1460 | DN250 | 375 |

350 | 350 | 350 | 350 | 350 | 360 | 20 | 855 | 1460 | DN250 | 390 |

400 | 400 | 400 | 400 | 400 | 415 | 23 | 922 | 1600 | DN300 | 455 |

450 | 450 | 450 | 450 | 450 | 450 | 25 | 922 | 1600 | DN300 | 465 |

500 | 500 | 500 | 500 | 500 | 510 | 28 | 1015 | 1712 | DN400 | 520 |

550 | 550 | 550 | 550 | 550 | 560 | 31 | 1015 | 1712 | DN400 | 550 |

注:1、产品最大工作压力为16kgf/cm2;

2、更大工作压力或特殊规格的过滤器请与沪盛公司联系。